By using pouches, HiPP not only meets consumer demands for lighter and more convenient packaging, it also remains true to its quality standards and its environmental awareness philosophy.

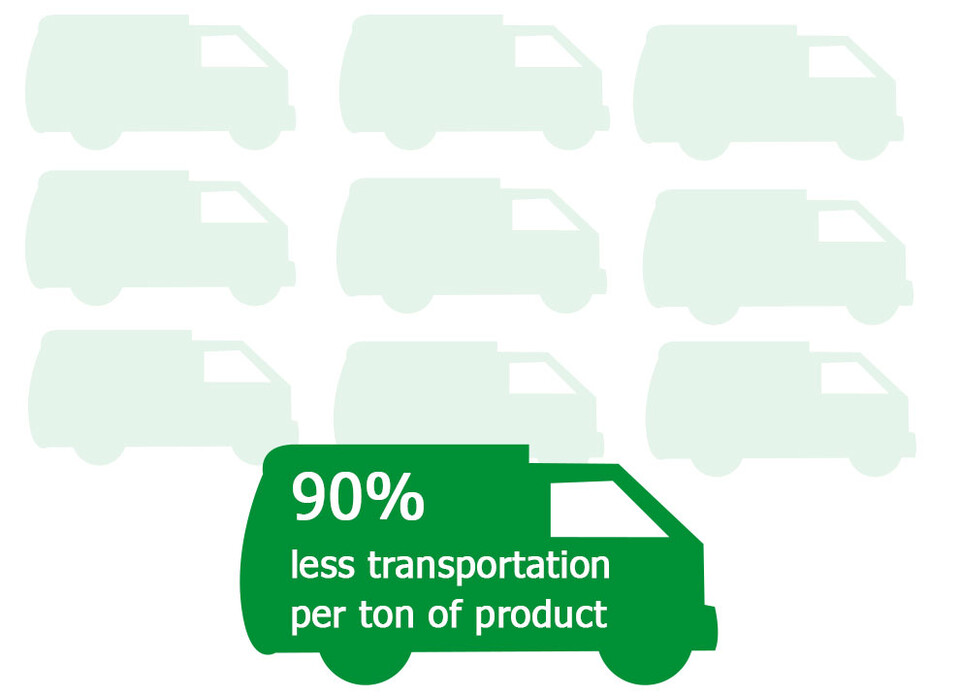

As pouches require less packaging material per gram of content, the German Packaging Ordinance rates the pouch as “ecologically advantageous” disposable drinks packaging, which is just as environmentally-friendly as reusable packaging. Therefore, this drinks packaging is exempt from the deposit charge in Germany.

HiPP pouches for children

HiPP uses this packaging because of its many benefits. Consumers like pouches because they are light, unbreakable, in good portion sizes, and are hygienic. Pouches are designed to ensure that the product is ideally protected and its premium quality is maintained even when stored unrefrigerated.